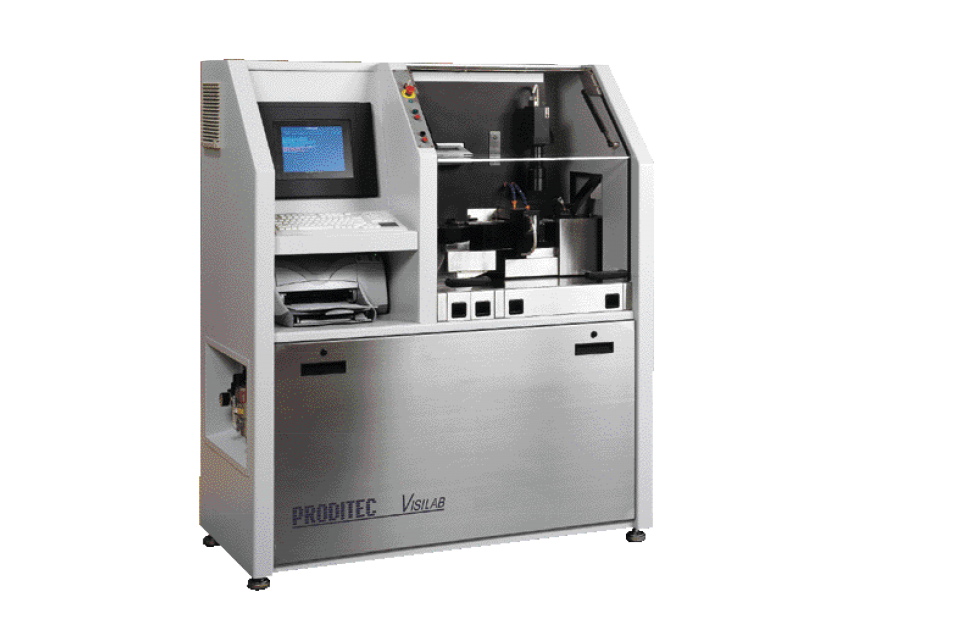

VISILAB: Precision Metrology for Coins and Blanks

VISILAB – Automated Coin and Blank Metrology

The Visilab is the EU-certified automated statistical control measurement tool. The Visilab will save you time on manually measuring the specified sample by giving you a final report that will allow you to release your batch from quality control.

The Visilab can handle blanks and coins.

| Features | VISILAB V2 |

|---|---|

| Inspection Capability | Processes up to 250 coins or blanks in 30 minutes |

| Key Parameters Measured | Outer Diameter, Ovality, Rim Height, Flatness, Conductivity, Plating Thickness, Weight |

| Material Compatibility | Bi-metal, Copper, Steel, Nickel, Aluminium |

| User Convenience | Self-calibrating cameras, Simple touchscreen interface, No setup required for circulating coins |

| Dimensions | 1,860 x 650 x 1,500 mm |

| Weight | Approx. 300 kg |

| Optional Features | Electro-magnetic property measurement, Field thickness analysis |

Discover our other inspection solutions

VISIA – Advanced & Blank Inspection

- Throughput: Up to 200,000 coins or blanks per hour

- Versatility: Compatible with various shapes (round, scalloped, bi-metallic) and materials (nickel, copper alloys, steel, aluminium)

- Inspection Precision: 100% surface inspection with cutting-edge 4-color matrix cameras

- User-Friendly Operation: Intuitive touchscreen interface and open architecture for easy maintenance