SOLUTIONS FOR THE MINTING INDUSTRY

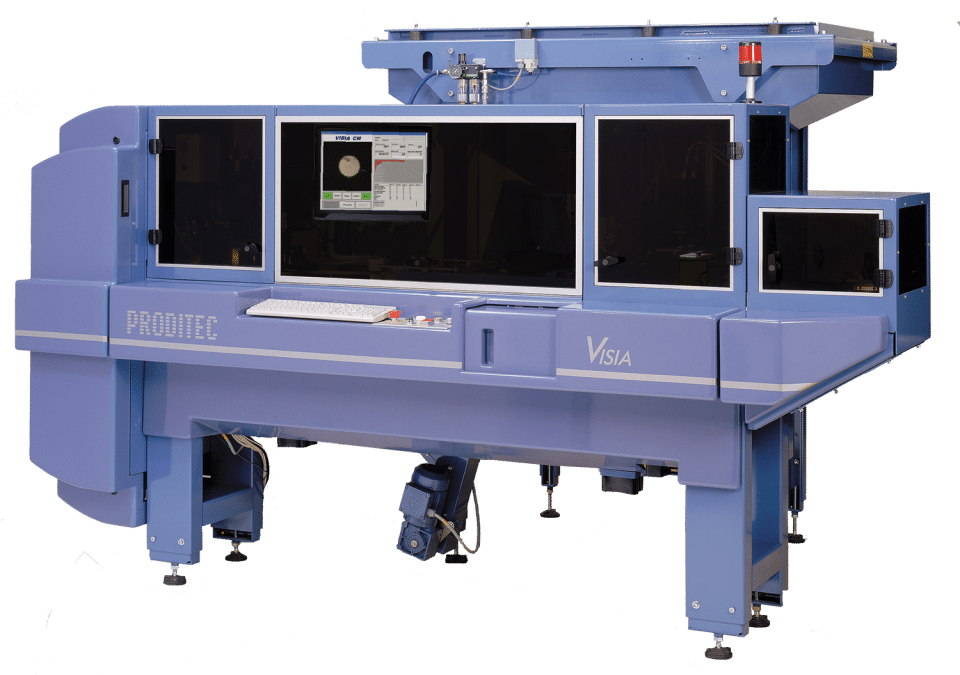

VISIA – HIGH-SPEED BLANK INSPECTION

Specialized for blanks

The Visia system is the global standard solution for blank inspection in the minting industry. Performing a 100% inspection for all circulating coin blanks allows for a secure and cost-effective striking process. In addition, it enables you to deliver the highest quality to your customers and maintain the perfect image of the issuing country.

The Visia CM is the latest version of the renowned Visia 100. It uses the latest technologies for high-performance, high-accuracy and high-volume blank inspection.

FEATURES

Speed: Up to 200,000 blanks per hour

100% surface inspection for all types of defects

All shapes: circular, scalloped, ringed, bi-metallic

All metals: nickel, copper alloys, steel, silver, aluminium, bi-metallic, etc.

Four color matrix cameras and one line scan camera (option for thickness control)

LED lighting

Touch-screen

Open architecture for easy operation and maintenance

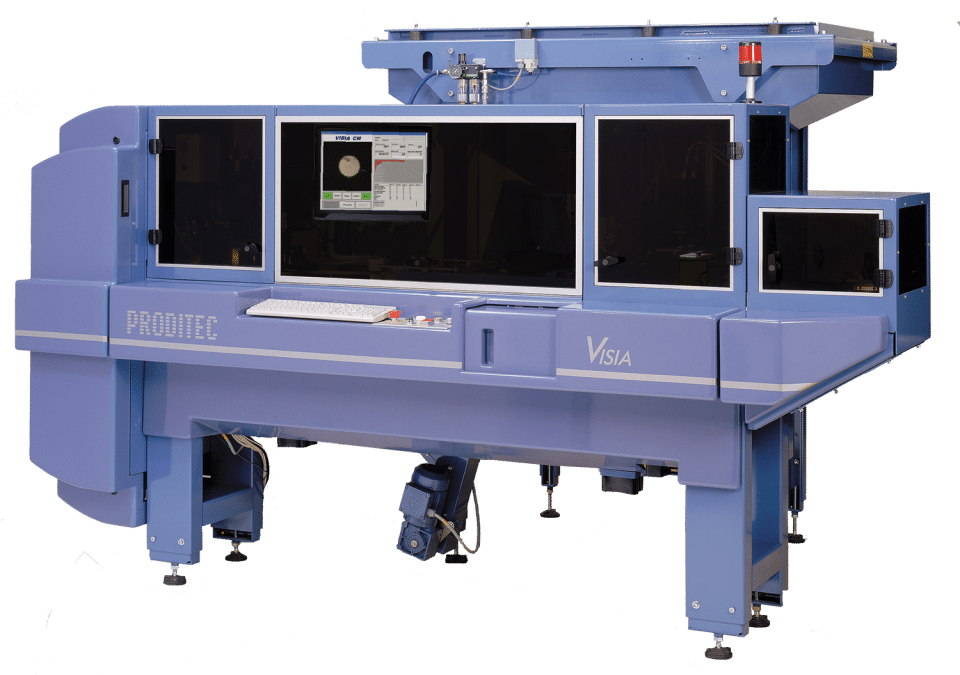

VISIA – HIGH-SPEED COIN & BLANK INSPECTION

Specialized for coins and blanks

The Visia system is the global standard solution for blank inspection in the minting industry. Performing a 100% inspection for finished, circulating coin and blanks allows for a secure and cost-effective striking process. In addition, it enables you to deliver the highest quality to your customers and maintain the perfect image of the issuing country.

The Visia CM is the latest version of the renowned Visia 100. It uses the latest technologies for high-performance, high-accuracy and high-volume blank inspection.

FEATURES

Speed: Up to 200,000 coins/blanks per hour

100% surface inspection for all types of defects

All shapes: circular, scalloped, ringed, bi-metallic

All metals: nickel, copper alloys, steel, silver, aluminium, bi-metallic, etc.

4-colour matrix cameras

LED lighting

Touch-screen

Open architecture for easy operation and maintenance

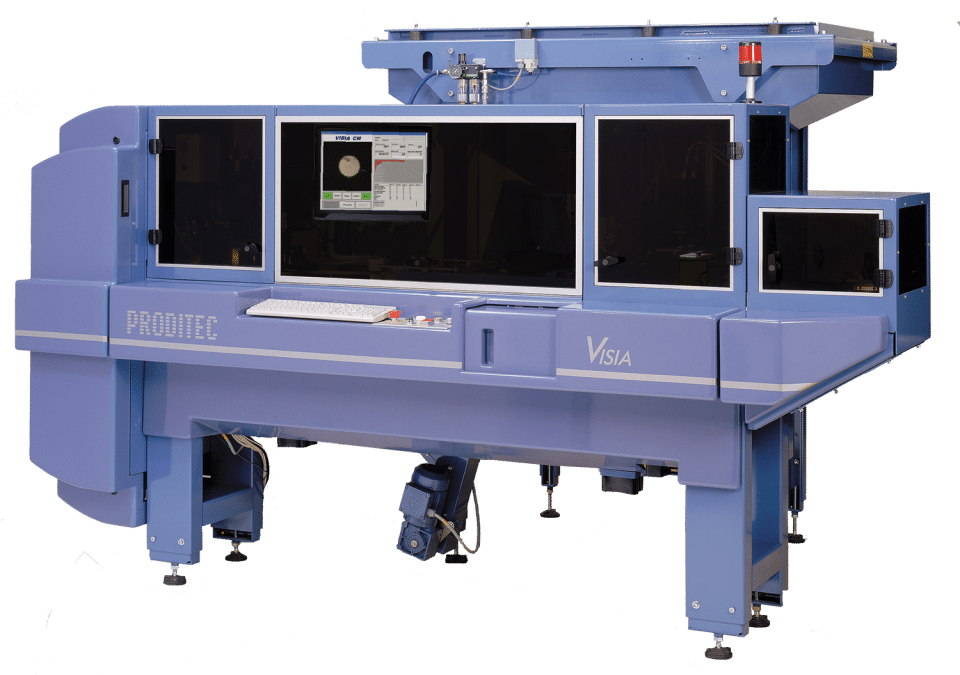

VISIA – HIGH-SPEED COIN & BLANK INSPECTION

Specialized for coins and blanks

The Visia system is the global standard solution for blank inspection in the minting industry. Performing a 100% inspection for finished, circulating coin and blanks allows for a secure and cost-effective striking process. In addition, it enables you to deliver the highest quality to your customers and maintain the perfect image of the issuing country.

The Visia CM is the latest version of the renowned Visia 100. It uses the latest technologies for high-performance, high-accuracy and high-volume blank inspection.

FEATURES

Speed: Up to 200,000 coins/blanks per hour

100% surface inspection for all types of defects

All shapes: circular, scalloped, ringed, bi-metallic

All metals: nickel, copper alloys, steel, silver, aluminium, bi-metallic, etc.

4-colour matrix cameras

LED lighting

Touch-screen

Open architecture for easy operation and maintenance

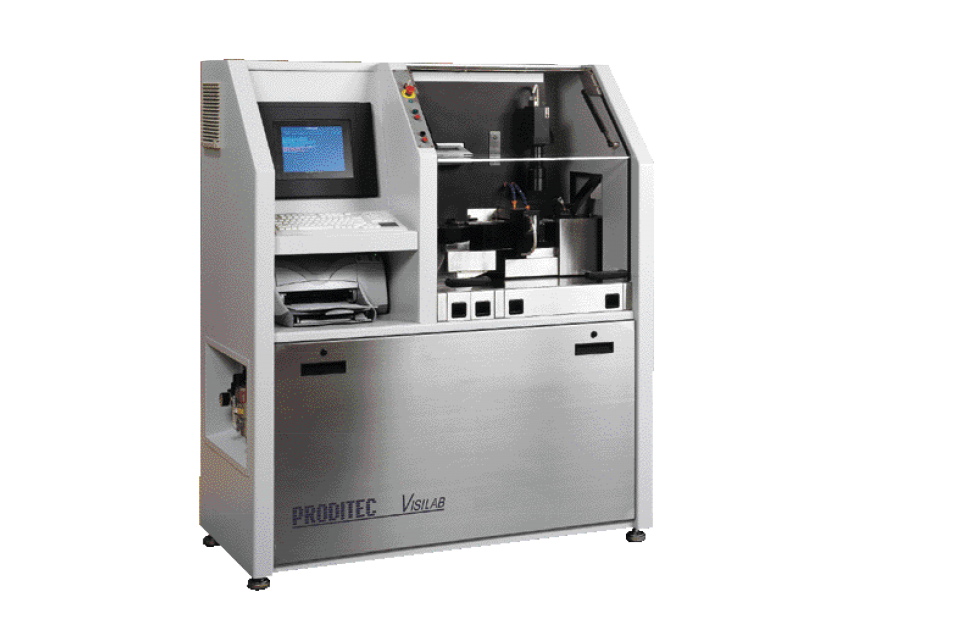

VISILAB – AUTOMATED COIN AND BLANK METROLOGY

The Visilab is the EU-certified automated statistical control measurement tool. The Visilab will save you time on manually measuring the specified sample by giving you a final report that will allow you to release your batch from quality control.

The Visilab can handle blanks and coins.